Our booth/展位

Hall 15, Booth D22/15号展厅,D22展位

At K 2022, Sumitomo (SHI) Demag showcases its in-mould decoration (IMD) process expertise, manufacturing a complex electric vehicle (EV) application on an all-electric IntElect2 220/660-1100 injection moulding machine. Creating a ‘smart’ e-charging Wallbox column, weighing 110 grams, in a 60 second cycle time, this new demonstration centres around sustainability. Despite its decor and complexity, the manufactured IMD part is especially durable due to its special material properties. Yet, the fully recyclable material used - a Makrolon RE polycarbonate supplied by Covestro - is also CO2-neutral.

在K 2022展会中,住友(SHI)德马格将在一台全电机IntElect2 220/660-1100上通过生产复杂的电动汽车用产品来展示其在模内装饰(IMD)加工方面的专业知识。一款重110g的Wallbox智能充电柱将在60s的循环时间内被生产出来,这项新展示也是围绕可持续性宗旨。虽然带有装饰且复杂,但特殊的材料性使这款IMD部件特别耐用。使用的材料是科思创的Makrolon RE聚碳酸酯,完全可回收,也是碳中性材料。

Control panel of a wallbox being produced using the IMD process at K 2022 on an all-electric injection moulding machine from Sumitomo (SHI) Demag/K 2022上,将使用IMD工艺在住友(SHI)德马格的全电动注塑机上生产的Wallbox的控制面板

Underpinning Sumitomo (SHI) Demag’s Act! Sustainably commitment, the company continues to take decisive action, stating that all future innovations, machines and equipment are now totally manufactured with this ecological mission and the EU Digital Product Passport (DPP) in mind. Accordingly, complete integration of IMD within the injection moulding process on this application eliminates any additional manufacturing steps. This processing synergy significantly reduces CO2 emissions and is therefore widely regarded as being more sustainable.

为履行可持续性宗旨,住友德马格行动果断,并表示:所有面向未来的创新、机器和设备,将完全遵循这个生态使命以及欧盟的数字化产品护照(DPP)来进行制造。相应地,在此应用中,将IMD工艺完全集成到注塑成型加工中,减少了额外的生产步骤。这种加工协同性显著降低了碳排放,因而更具可持续性。

Rustam Aliyev, Director Business Development Automotive & Electronic/汽车及电子业务开发总监

A cooperation involving numerous partners and sustainability influencers, the K 2022 Wallbox project showcases the very best industry expertise and innovations, reports Rustam Aliyev, Director Business Development Automotive & Electronic.

Wallbox是一项涉及众多合作伙伴及具有可持续性影响力的项目,在K 2022中将展示更多的行业专业知识和创新,住友德马格汽车及电子业务开发总监Rustam Aliyev表示。

Alongside Sumitomo (SHI) Demag and Covestro, KURZ presents its newest functionality and decorative manufacturing techniques. Frimo supplies the sprue separation system, Acsys provides the laser, and schöfer, a KURZ subsidiary, the tooling technology. The temperature control systems and material drying process are designed by Piovan.

除住友德马格和科思创外,KURZ公司还将展示新的功能和装饰制造技术,Frimo公司将展示浇口分离系统, Acsys公司将提供激光器,KURZ的子公司schöfer则提供模具技术,Piovan公司则设计温度控制系统和材料干燥工艺。

Describing the extent of the technological advances accomplished by this Wallbox project, Rustam references the separation of component sprues after the injection process using a milling head equipped with clean room technology. “This single process ensures that particles are extracted in a controlled manner. Showcasing what can be achieved when likeminded industry innovators come together to resolve specific processing challenges.”

以“注塑成型后采用装有洁净室技术的铣头来分离部件的浇口”为例,Rustam介绍了Wallbox项目所取得的技术进步:“这种单一工艺确保了塑料粒子能以可控的方式被提取出来,展示了当志同道合的行业创新者联合起来应对特定的加工挑战时所取得的成就。”

Sustainability pioneer KURZ also shares its extensive decoration experience. The company’s use of thin-film technology ensures recyclability of the components isn’t compromised. Additionally, by integrating the resource-saving IMD process into production means that extra drying energy is no longer required. This also eliminates wet paint contamination. Thus reducing component defects and consequently waste.

可持续先锋KURZ还将分享其丰富的装饰技术经验。使用的薄膜技术确保了部件的可回收性不受影响。此外,将节能的IMD工艺集成到生产中,意味着不再需要额外的能耗来进行干燥。这还消除了因上漆带来的污染问题,从而减少了部件缺陷和相应的废品。

Application-specific automation/为应用订制自动化

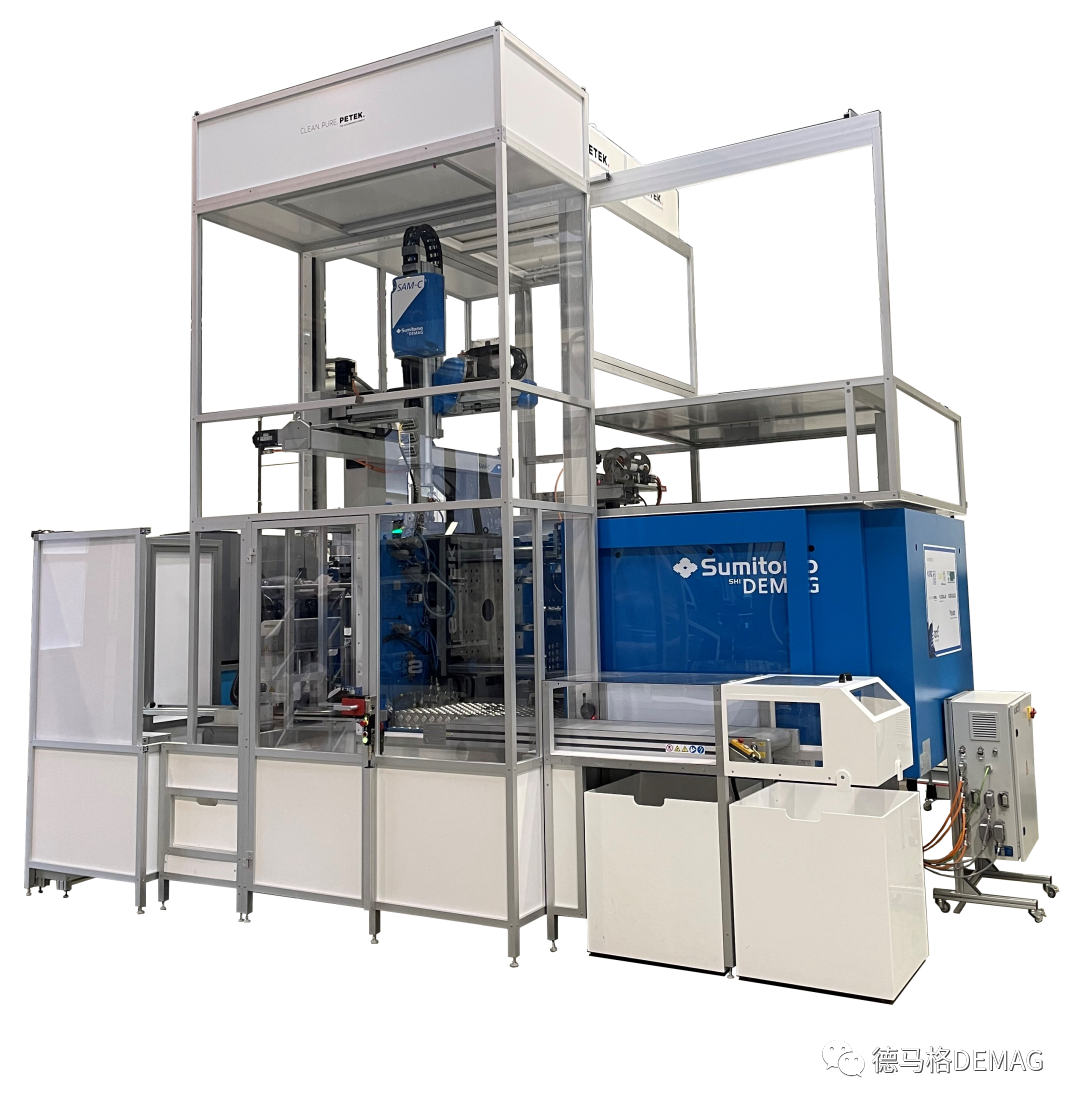

Showcasing the company’s Customised Automation competence, the Wallbox production cell features a 5-axis linear robot SD 22x, underlining the successful and long-standing partnership Sumitomo (SHI Demag continues to enjoy with Sepro.

为了展示公司订制自动化的能力,Wallbox生产单元采用了一台5轴线性机械手SD 22x,强调了住友德马格持续享有与Sepro公司之间的成功而长期的合作伙伴关系。

Production cell for manufacturing a wallbox control panel at K 2022/K 2022上,将用于制造Wallbox控制面板的生产单元

For optimal efficiency, this 5-axis robot performs multiple tasks, including removing the moulded Wallbox component and inserting the decorative film, which is then back-injected. Two servo rotation axes guarantee precision and reliability. Next, the Wallbox control panel is transported to the milling station, where separation of the gates occur.

为达到效率,这台5轴机械手执行多项任务,包括:取出成型好的Wallbox部件,埋入装饰薄膜以便进行背部注塑。两个伺服旋转轴确保了精度和可靠性。下一步,机械手将Wallbox控制面板输送到铣削站,在那里对浇口进行分离。

AfiPro (formerly H+S Automatisierungstechnik) then introduces the ensuing automation, delivering a seamless process from start to end. “The entire process flow is designed to reduce operating effort and minimise footprint within customer plants. This exhibit is an exemplary example of how to apply Customised Automation to meet a specific application processing requirement, using flexible, easy-to-operate robotics within an injection moulding cell,” claims the automotive and electronics expert.

后续的自动化技术则由AfiPro公司(以前的H+S Automatisierungstechnik公司)提供,以确保加工从头到尾都能无缝衔接。“整个工艺流程的设计减少了操作,并大程度地减少了生产单元在客户工厂的占地面积。这项展出为如何利用订制自动化来满足特定的加工应用需求,从而在注射单元中使用灵活的易于操作的机械手而作出了典范。”Rustam说道。

The system’s modular design showcases how a single cell can easily switch between manufacturing simple and highly complex parts, highlights Aliyev. "The digitisation of components and design elements combined with extremely durable finishes for a large number of product variants, using one operation offers manufacturers significant cost savings." Referencing the design and production of EV smart charging technology, Aliyev adds: "The ability to introduce partial lighting, optional sensors and displays for maximum functionality is a good example of how processes can be adapted to meet the growing needs for high-quality, bespoke and diverse product ranges that are also energy-efficient and resource-saving."

该系统的模块化设计展示了单独的生产单元如何在简单部件与复杂部件的生产间轻松切换。Aliyev强调说:“部件的数字化和设计元素再结合高度的耐久性表明,对于各种不同的产品生产而言,采用一次性操作可使生产商显著降低成本。”以设计和生产电动汽车用的智能充电技术为例,Aliyev补充道,引入局部照明、可选传感器和显示器以实现大功能的能力,很好地说明了如何通过调整工艺来满足日益增长的对高质量、订制化和多样化产品系列的需求,这些产品同时也是节能的和资源节约型的产品。”

A direct advantage of the IntElect2’s parallel axis and closed toggle lever technology, which maximises the platen parallelism movements, are the extremely low reject rates. This outstanding processing precision, characterised by excellent dynamics and high energy efficiency, significantly contributes to the project’s success, reports Aliyev. The IntElect2 220/660-1100, that’s integral to this K 2022 demonstration, features the company’s newest servo drives, delivering even greater repeatability and shorter cycle times.

IntElect2注塑机的平行轴和封闭的曲肘杆技术,极大地提高了模板运行的平行度,带来的极大好处是显著降低了废品率。Aliyev表示,这种出色的加工精度,以***的动态和高能效为特征,为项目的成功做出了巨大贡献。在K 2022中演示的IntElect2 220/660-1100注塑机采用了住友德马格***的伺服驱动技术,确保了更高的加工可重复性和更短的循环时间。

As a result of Sumitomo (SHI) Demag’s proprietary drive motors, the IntElect series uses up to 20 percent less energy than conventional all-electric injection moulding machines. Making it one of the more energy efficient machines on the market, reports Aliyev. Higher availability and greater precision are additional efficiency advantages. All process-relevant interfaces are integrated into a single control system, including all of the IMD and robotic communications.

由于采用了住友德马格专有的驱动电机,IntElect系列注塑机的能耗要比传统的全电动注塑机低20%,这使之成为市场上较为节能的机器之一,Aliyev说道。其他的效率优势是更高的使用率和更高的精度。所有与加工相关的界面都被集成到一个控制系统中,包括所有IMD和机械手的通讯。

Sumitomo (SHI) Demag invites you to witness more surprises! If you have any questions, please feel free to contact us./住友(SHI)德马格邀请您来现场见证更多惊喜!如有任何问题,请随时联系我们。